Valves - Stauff USA

Valves control, regulate, and direct the flow of fluids in industrial systems. They keep water, steam, chemicals, gases, slurries, and light oils moving safely and efficiently. A valve either shuts flow off complet...

When it comes to instrumentation systems, precision and reliability are key. Pipes, valves, and fittings (PVF) are critical in maintaining accurate measurements, controlling pressure, and ensuring smooth operation in industrial processes. Stauff PVF products are designed to handle high pressures, temperature fluctuations, and corrosive environments, making them ideal for industries like oil and gas, chemical processing, power generation, and manufacturing.

What Stauff PVF Products Does Centro Offer?

Centro provides a full range of Stauff PVF components built for instrumentation applications, including:

- Instrumentation tubing – High-quality stainless steel tubing for precise fluid and gas control.

- Needle valves – Allow for fine adjustments and accurate flow regulation.

- Ball valves – Provide quick on/off control for efficient system management.

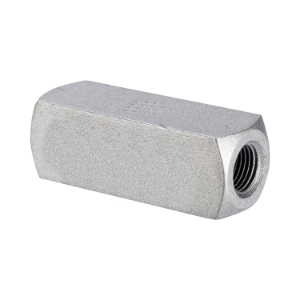

- Check valves – Prevent backflow and protect sensitive instrumentation.

- Tube fittings and adapters – Available in various configurations to ensure leak-free connections.

- Manifold valves – Streamline pressure control and system isolation in complex setups.

Why Choose Stauff PVF Products?

- Precision-engineered for demanding applications.

- Corrosion-resistant materials ensure durability in harsh environments.

- Leak-free performance keeps systems running efficiently.

- Wide compatibility with different instrumentation setups.

Find the Right PVF Solution

Whether you're setting up a new instrumentation system or upgrading existing components, Stauff PVF products offer the reliability and performance you need. Browse our selection online or reach out to our team for expert guidance in choosing the right components for your application.

Centro offers a reliable selection of ball valves or flow control valves designed for smooth operation and long-lasting performance in a wide range of applications. These quarter-turn valves provide tight shutoff capabilities, making them ideal for use in fluid systems requiring low torque and minimal leakage.

Ball Valves are available in a variety of materials including brass, stainless steel, and PVC, our solutions support industrial needs. Whether you're managing water, oil, gas, or chemical flow, Centro's valve options ensure durability and precise control.

With configurations ranging from full port to reduced port and options for 1-piece, 2-piece, and 3-piece designs, we provide flexibility for everything from general plumbing to high-pressure industrial systems.

Explore our complete range of ball valves to find the right fit for your application or contact our experts for personalized guidance.

Check valves are mechanical devices designed to allow fluid—whether liquid or gas—to flow in only one direction, preventing backflow that can damage equipment or disrupt system performance. Commonly used in industrial, plumbing, and MRO (maintenance, repair, and operations) systems, they automatically open with forward flow and close when flow reverses. Available in various types like swing, ball, and inline designs, check valves are essential for ensuring system integrity, protecting pumps and compressors, and maintaining operational safety.

Types of Check Valves We Offer:

- Swing Check Valves – Ideal for irrigation and low-pressure systems

- Ball Check Valves – Reliable for wastewater and slurry applications

- Piston Check Valves – Designed for precise flow control in hydraulic systems

Centro partners with leading manufacturers to provide top-quality materials and engineering in every check valve we supply. Browse our extensive selection and find the perfect check valve for your needs. Order online today or contact our experts for assistance!

Valve accessories are additional components that enhance the functionality and performance of valves in fluid control systems. These accessories are designed to provide other features, improve safety, or simplify maintenance of the valves. Valve accessories enhance the reliability, efficiency, and safety of valve operations, making them essential for various industries such as oil and gas, chemical processing, water treatment, and power generation.

Flow control valves are essential devices used in fluid control systems to regulate the flow rate within a pipeline or system. These valves allow for precise adjustment of flow rates, ensuring optimal performance and efficiency. By controlling the opening or closing of the valve or by using throttling mechanisms, flow control valves can increase or decrease the flow rate as desired. This enables operators to maintain stable flow conditions, prevent fluid overload, and achieve accurate flow control for various applications. Flow control valves are commonly used in manufacturing, oil and gas, water treatment, and HVAC systems, where precise flow management is critical for operational success.

Hydraulic filters are components designed to remove contaminants from hydraulic fluids, for a smooth and efficient operation of hydraulic systems. These filters protect critical components such as pumps, valves, and actuators from damage caused by particles, water, and other impurities, reducing wear and extending equipment life. Available in a variety of types, including suction, pressure, and return-line filters, they are tailored to meet specific system requirements and performance needs. At Centro, we provide high-quality hydraulic filters that help maintain system reliability and reduce downtime. Contact us to learn more about our hydraulic filtration solutions.

Valve repair kits and parts are essential components used to maintain and repair valves in fluid control systems. These kits typically include seals, gaskets, o-rings, springs, and other necessary parts needed to restore or replace worn or damaged elements of a valve. Valve repair kits and parts enable the repair and refurbishment of valves, extending their lifespan and ensuring proper functioning. By using these kits, operators can quickly and cost-effectively address valve issues without requiring complete valve replacement. These kits are available for different types and sizes of valves, allowing for specific repairs tailored to the valve's design and requirements. Valve repair kits and parts are essential for industries such as manufacturing, petrochemicals, water treatment, and HVAC, where reliable valve performance is crucial.

Needle valves are essential for controlling fluid flow with high precision in industrial and commercial applications. These valves feature a small, tapered stem that allows for fine adjustments, making them ideal for systems that require accurate flow regulation. Commonly used in industries such as chemical processing, oil and gas, water treatment, and instrumentation, needle valves help maintain efficiency and process stability.

Types of Needle Valves

Centro offers a variety of needle valves designed to meet different application requirements, including:

- Standard needle valves for general-purpose flow control in low- to medium-pressure systems.

- High-pressure needle valves built for demanding applications with extreme pressure conditions.

- Instrumentation needle valves for precise flow adjustments in analytical and laboratory settings.

Choosing the Right Needle Valve

Selecting the appropriate needle valve depends on factors such as system pressure, temperature, fluid type, and required flow control precision. Consider whether the valve needs to handle gases or liquids, as well as the level of adjustability required for your application.

Browse our selection of needle valves online or contact our team for expert assistance in choosing the right solution for your system.

$2,010.49$2,185.31

Subject to factory lead times

$98.88$107.47

Subject to factory lead times

$138.02$150.02

Subject to factory lead times

$201.44$218.95

Subject to factory lead times

$350.26$380.71

Subject to factory lead times

$57.13$62.09

Subject to factory lead times

$61.52$66.86

Subject to factory lead times

$104.15$113.20

Subject to factory lead times

$186.73$202.96

Subject to factory lead times

$104.15$113.20

Subject to factory lead times

$1,132.03$1,230.46

Subject to factory lead times

$849.05$922.87

Subject to factory lead times

$2,010.49$2,185.31

Subject to factory lead times

$98.88$107.47

Subject to factory lead times

$138.02$150.02

Subject to factory lead times

$201.44$218.95

Subject to factory lead times

$350.26$380.71

Subject to factory lead times

$57.13$62.09

Subject to factory lead times

$61.52$66.86

Subject to factory lead times

$104.15$113.20

Subject to factory lead times

$186.73$202.96

Subject to factory lead times

$104.15$113.20

Subject to factory lead times

$1,132.03$1,230.46

Subject to factory lead times

$849.05$922.87

Subject to factory lead times