Centro Central Blog

Read the latest news and updates from Centro, Inc.

Featured Posts

%20(1).webp?width=1688&height=949)

.webp?width=1688&height=949)

Pump & Seal

General

2/28/2025 |Centro

Announcements

2/28/2025 |Centro

Announcements

Instrumentation, Measurement & Control

4/1/2025 |Centro

Case Studies

11/12/2024 |Jerry Walling

Articles

Automation & Robotics

Filtration & Process Systems

1/2/2025 |Centro

Announcements

Bulk Material Handling & Dust Collection

9/24/2024 |Ramsey Roberts

Articles

Valve, Actuation & Engineered Products

"Our mission is to be regarded by our customers and our community as the best supplier of automation and control product solutions to industry."

Michael R Gallagher

Centro President

Shop Centro Products

Bimetal thermometers are widely used temperature measurement devices that employ a bimetallic strip to indicate temperature changes. These thermometers consist of two metal strips, typically made of different metals with different coefficients of thermal expansion, bonded together. The metals expand or contract at different rates as the temperature changes, causing the bimetallic strip to bend. This bending motion is then translated into a rotational movement displayed on a calibrated dial to indicate the temperature. Bimetal thermometers are known for their simplicity, durability, and cost-effectiveness. They are commonly used in various industries and applications requiring reliable temperature monitoring, such as HVAC systems, automotive, food processing, and industrial processes. Bimetal thermometers offer advantages such as wide temperature ranges, resistance to shock and vibration, and ease of installation. They are available in different sizes and configurations to suit specific application requirements. With their robust construction and accurate temperature indication, bimetal thermometers provide a reliable and cost-effective temperature measurement solution in various industrial and commercial settings.

Process gauges are instruments explicitly designed for monitoring and measuring pressure in industrial processes. They are built to withstand harsh operating conditions, such as high temperatures, corrosive environments, or high pressure levels. Process gauges are commonly used in industries like oil and gas, chemical manufacturing, and power generation, where accurate and reliable pressure monitoring is crucial.

Configured drives are tailored drive systems designed to meet specific application needs in industrial settings. Configured Drives combine motors, variable frequency drives (VFDs), and control components into a single package, simplifying installation and operation. By pre-configuring the drive parameters, they save time on setup and provide optimal performance right out of the box. Configured drives are particularly valuable in applications where precise speed control, energy efficiency, and seamless integration with existing systems are critical. They also often include advanced features like remote monitoring and diagnostics, making them a reliable choice for demanding environments like manufacturing, HVAC, or material handling. Browse Centro's product offerings below or contact us to speak with a product expert to help you with your selection, and possible make customizations for you.

Centro’s Filtration division helps businesses run smoothly by providing high-quality filtration solutions that remove contaminants, protect equipment, and improve product quality. Whether air or liquid filtration, Centro offers reliable products that help extend equipment life and maintain efficiency. They work with food processing, chemical production and manufacturing industries to provide customized solutions that meet specific needs. With expert support and a focus on innovation, Centro ensures businesses have the filtration they need to keep their processes clean, safe, and efficient.

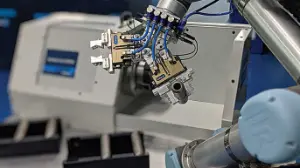

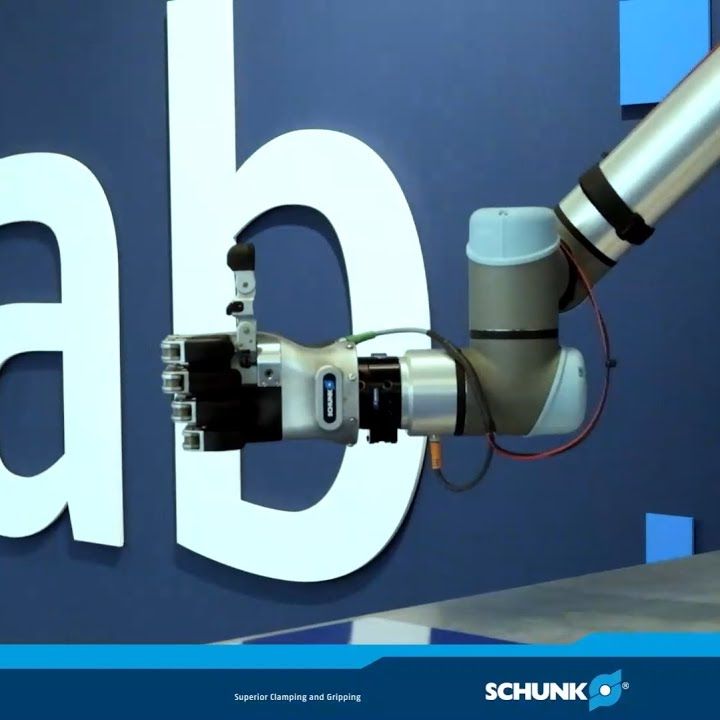

Grippers and end-of-arm tooling (EOAT) are vital in robotic and automated systems due to their versatility and customization. They handle tasks from simple pick-and-place to complex assembly and packaging, making them suitable for various industries. By integrating EOAT, robots perform repetitive tasks more efficiently and quickly than humans, boosting productivity. The precision of EOAT ensures high-quality outcomes and reduces errors, vital for sectors like electronics, pharmaceuticals, and automotive manufacturing. EOAT enhances workplace safety by taking over dangerous, heavy, or repetitive tasks, improving ergonomics and reducing the risk of injury. Centro offers a complete selection of grippers and end-of-arm tooling (EOAT) products. Our wide range of grippers ensures that you can find the ideal solution for any specific application.

What types of grippers does Centro provide, and what do they do?

- Pneumatic Grippers: Ideal for applications requiring a high degree of skill, these grippers use compressed air to handle objects precisely and flexibly.

- Angular Grippers: Used for picking up objects from inclined surfaces, these grippers can grasp items at various angles, making them versatile for complex tasks.

- 4-Finger Grippers: Provide a wide range of motion and allow for the delicate handling of small parts. They are instrumental in applications requiring gentle manipulation and high precision.

- O-Ring Grippers: Perfect for applications requiring frequent part or tool replacement, these grippers are designed to handle O-rings and similar objects efficiently and with minimal wear.

- Magnetic Grippers: Utilize magnetic force to lift and move heavy materials, offering a reliable and efficient solution for handling metal objects.

- Vacuum Grippers: Use suction to pick up and transport objects, ideal for handling smooth, non-porous surfaces and delicate items.

- Electrical Grippers: Provide precise control and easy integration with various robotic systems, suitable for applications requiring accurate and repeatable gripping.

- Gripper Accessories: Enhance the functionality and versatility of grippers, including items such as finger kits, sensors, and mounting brackets.

Why should I choose Centro for end-of-arm tooling (EOAT)?

Centro offers a diverse selection of high-quality EOAT products that cater to various industrial needs. Whether you need precision, versatility, or specialized solutions, Centro has the right gripper for your robotic automation needs.

Unsure what product(s) you need for your application and need help?

Contact us to speak to a product expert to assist you in every step of the way from product selection to installing.

Efficiently manage and transport large volumes of material with our comprehensive range of bulk material handling solutions. This category features an array of products designed for industrial applications, including conveyors, hoppers, bins, feeders, and storage systems. Ideal for industries such as agriculture, mining, manufacturing, and logistics, these products ensure smooth material flow, enhance productivity, and reduce downtime.

Whether you need to move powders, grains, or heavy materials, our equipment is built to handle various capacities and material types with durability and precision. Explore solutions that prioritize safety, optimize operations, and meet the rigorous demands of bulk material handling tasks. With trusted brands and customizable options, we’re your one-stop source for high-performance material handling equipment.

Keep your operations running smoothly with our selection of Fans and Blowers, designed to meet industrial environments' airflow and ventilation needs.

Designed for performance and efficiency, our fans and blowers are perfect for cooling machinery, managing air quality, and venting hazardous fumes. Whether you need compact designs for tight spaces or heavy-duty options for demanding environments, our products deliver reliable performance, energy efficiency, and long-lasting durability.

Enhance air circulation, and worker safety, and improve your facility's environment with our ventilation solutions. Browse our product selection or contact us to speak with a product expert to help you with your selection.

Centro carries a wide range of mechanical cleansing products to suit industrial or commercial needs. Mechanical cleaning uses physical force to remove dirt, debris, and other contaminants from surfaces. This can be done using various methods, including backwash cleaning and mechanical self-cleaning. Backwash cleaning is a type of mechanical cleansing that uses high-pressure water to remove contaminants from surfaces. This method is often used to clean industrial equipment and machinery. Mechanical self-cleaning refers to using physical tools and devices to remove contaminants from surfaces. This includes brushes, scrapers, and high-pressure air jets. Centro's selection of mechanical cleansing products is available online, making it easy to find the right product for your needs.

Robotics is a rapidly growing field in industrial settings, and there is an increasing demand for Robotics products and solutions in manufacturing settings. Industrial Robotics is the application of robots in an industrial environment. You will find industrial robotics in all industries, including automotive, food and beverage, pharmaceuticals, and electronics. Robotics offers many advantages over traditional manufacturing methods, including increased productivity, accuracy, and safety. We are experts in a wide range of robotics products, including Robotics Kits, Robotics Controller Boards, Robotics Software, Robotics Motors, Robotics Sensors, Robotics Cameras, and more. Centro has a complete selection of industrial robotics components available online, including general robotic products and Pre-Engineered Cells.

Centro provides complete electrical heat tracing solutions to keep pipes, tanks, and equipment operating safely in cold or temperature sensitive environments. Our heat cables and pipe tracing systems deliver steady, controlled warmth along the length of a pipe or across equipment surfaces to prevent freezing, maintain flow, and keep liquids, chemicals, or other materials at the proper operating temperature.

These systems are essential in industries like chemical processing, food and beverage, water treatment, oil and gas, and manufacturing where unprotected lines can freeze, burst, or cause costly shutdowns. Heat tracing can be used on everything from small water lines and process piping to large storage tanks, pumps, and valves, for reliable performance even in harsh outdoor or unheated indoor spaces.

Centro works with manufacturers like Nelson Heat Trace to provide high quality heating cables, controls, and accessories. Our team offers assistance with product selection and technical support so you get a system that is efficient, safe, and built to last for your specific application. Whether you need freeze protection, temperature maintenance, or process control, Centro can help you choose the right heat tracing solution for long term reliability.

Air regulators are devices used to control and maintain a consistent and adjustable pressure level in compressed air systems. They are essential for optimizing the performance of pneumatic tools, actuators, and other air-powered equipment. Air regulators monitor the incoming air pressure and regulate it to a desired setpoint, ensuring reliable and consistent operation. They provide precise control over the air pressure, allowing users to adjust and maintain the optimal pressure for specific applications. Air regulators are available in various configurations, including relieving and non-relieving types, with features like pressure gauges and lockout options, offering flexibility and functionality for different pneumatic systems.

Steam traps are automatic valves that filter out condensate and non-condensable gases such as air without allowing steam to escape. In the industry, steam is utilized regularly for heating or as driving energy for mechanical power. Steam traps prevent condensation from being wasted. There are three types of steam traps thermostatic, mechanical, and thermodynamic. Thermostatic steam traps act in response to the surrounding steam temperature. There are three types of thermostatic steam traps liquid expansion traps, bimetallic and balanced pressure thermostatic traps. Each operates differently and is suited to specific kinds of applications. Mechanical steam traps depend on the difference in density between steam and condensate. They can constantly pass large volumes of condensate and are fit for a wide range of process applications. Mechanical steam trap types include ball float and inverted bucket steam traps.

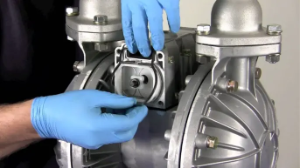

Industrial pumps move liquids from one place to another, whether you’re handling water, chemicals, or thick, heavy fluids. Most pumps fall into one of two main categories: positive-displacement pumps and centrifugal pumps (also called non-positive-displacement pumps).

Positive-displacement pumps move a set amount of liquid each cycle using seals or valves. They’re the go-to choice for thicker, high-viscosity materials—like slurries, oils, or adhesives—because they deliver a steady, reliable flow. Centrifugal pumps use rotating impellers to keep liquid moving, making them ideal for high-volume jobs like circulating water, solvents, chemicals, and light oils.

At Centro, we carry a full range of industrial pumps to match almost any process or application. Our selection includes air-operated double diaphragm (AOD) pumps, lobe pumps, submersible pumps, hose/peristaltic pumps, metering pumps, progressive cavity pumps, sealless mag-drive pumps, hydraulic pumps, and a variety of pump control systems.

Whether you’re looking for precision metering, chemical compatibility, or rugged performance, our team can help you find the right pump for the job. Browse our pump categories to compare options, or call Centro for expert guidance on selecting the best pump for your operation.

.webp?width=600&height=350)

.webp?width=300&height=168)

.webp?width=600&height=366)

.webp?width=1920&height=1920)

.webp?width=1688&height=949)