Robotics

Robotics is a rapidly growing field in industrial settings, and there is an increasing demand for Robotics products and solutions in manufacturing settings. Industrial Robotics is the application of robots in an in...

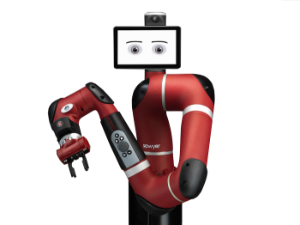

Industrial robots are programmable, automated machines designed to handle repetitive or complex tasks with precision and speed in manufacturing and production settings. They can weld, assemble, paint, pick and place items, or inspect products, all with consistent quality and minimal human error. Used in industries like automotive, electronics, metalworking, and packaging, industrial robots improve efficiency, reduce labor costs, and enhance workplace safety by taking on dangerous or demanding jobs. Their flexibility and reliability make them essential tools for modern factories aiming to boost productivity and maintain high standards of quality.

Robot accessories in the industrial sector are the driving force behind precision, productivity, and safety in the world of automation. These essential components, designed to complement robotic systems, encompass many tools and peripherals. Industrial robot accessories are the backbone of modern manufacturing from grippers and end effectors tailored to handle diverse materials to sensors, vision systems, and controllers that enable robots to adapt to their surroundings and perform intricate tasks with precision. Whether it's optimizing production lines, streamlining processes, or ensuring the utmost quality control, these accessories empower industries to stay competitive, efficient, and responsive to the ever-evolving demands of a dynamic marketplace.

Magnetic Automation Tooling is a cutting-edge solution designed to optimize and streamline complex manufacturing and industrial processes through the use of precision automation technologies. By leveraging the power of magnetic force in combination with automated systems, this tooling enhances efficiency, accuracy, and repeatability in tasks such as material handling, assembly, and inspection. It is particularly effective in environments that require non-contact or low-friction movement, making it ideal for delicate components or high-speed operations. Magnetic automation tooling not only reduces mechanical wear and maintenance needs but also supports customizable configurations, enabling seamless integration into diverse production lines. This innovative approach helps businesses achieve higher throughput, improved safety, and lower operational costs.

$19,875.00$45,428.57

$47,250.00$51,666.67

$31,846.25$34,900.00

$438.11

Subject to factory lead times

$39.89

Subject to factory lead times

$40.35

Subject to factory lead times

$58.66

Subject to factory lead times

Subject to factory lead times

Subject to factory lead times

$66.25

Subject to factory lead times

$137.91

Subject to factory lead times

$19,875.00$45,428.57

$47,250.00$51,666.67

$31,846.25$34,900.00

$438.11

Subject to factory lead times

$39.89

Subject to factory lead times

$40.35

Subject to factory lead times

$58.66

Subject to factory lead times

Subject to factory lead times

Subject to factory lead times

$66.25

Subject to factory lead times

$137.91

Subject to factory lead times