content loaded

Image may not be the actual product. Please refer to the full technical specs and MPN for exact details.

Available for Purchase

Get a delivery date for my location

Subject to factory lead times

$1,386.35

Questions? Call 1-866-703-5665

Expedited Shipping, Delivery Date, Product Questions & Help

Need more product options?

Access more configuration options through the Milwaukee Cylinder product configu Milwaukee Cylinder products

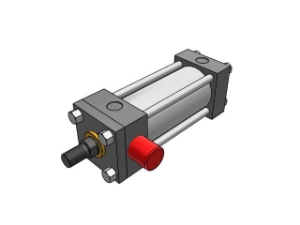

Milwaukee Cylinder H01532-71-24-7x8" - Heavy Duty NFPA Hydraulic Tie Rod Cylinder

MPN: H01532-71-24-7x8"

Available for Purchase

Get a delivery date for my location

Subject to factory lead times

$1,386.35

Questions? Call 1-866-703-5665

Expedited Shipping, Delivery Date, Product Questions & Help

Need more product options?

Access more configuration options through the Milwaukee Cylinder products

- Overview

- Features

- Specifications

Milwaukee Cylinder - Heavy Duty Hydraulic NFPA Tie Rod Cylinder, 3.25 Inch Bore, 2 Inch Rod Size, Rod End Trunnion Mount (H71/MT1), Cushining Both Ends, Small Male(KK2) Rod End Style, NPT Ports, Pressure Rating: 3000 PSI, Seals: Buna. Note: Many other sizes, mounting options, rod ends styles, seal material, and custom designs are available. Contract Centro to discuss your application.

- Removable Retainer Plate - The retainer plate and rod bushing are externally removable without disassembling the cylinder. Four cap screws securely hold and lock the retainer plate in place.

- Rod seals - The standard rod seal package includes 3 seals, two of which are fiber reinforced. This type of seal package is very durable and resistant to contamination - it takes longer for contamination to damage 3 seals, especially fiber reinforced seals. Most other cylindrer manufacturers use a one seal design that is not fiber reinforced. Note: Milwaukee Cylinder offers other seal packages that are optimized for various application situations - contact Centro to discuss your application.

- Piston Rod: The piston rod is made of high strength steel, hardened and chrome plated to resist scoring and corrosion, assuring maximum life. All rods are built and tested to stringent straightness standards.

- Piston: The piston is made of fine grained alloy iron, incorporating a unique combination of u-cup seals and cast iron rings. The cast iron rings are outboard of the u-cup seals and act to mitigate pressure surges felt at the u-cup seals and also help to reduce contamination exposure to the u-cup seals. This unique seal package is designed for long life and exceptional hi-lo pressure performance.

- Cylinder Barrel: The barrel is made of steel tubing, honed to a fine finish to assure superior sealing, minimum friction, and maximum seal life. As a result of our honing process, Milwaukee Cylinder pistons are oversized compared to the industry, resulting in slighly more force available from Milwaukee Cylinders pistons vs. other cylinder manufacturers.

- Barrel Seals: Milwaukee Cylinder utilizes a unique step cut on the O.D. of both tube ends for an o-ring and molded back-up washer. This sealing design provides a non-extrusion, positive leak proof seal performance.

- End Caps: End caps and mountings are made of high quality steel, precisioned machined for accurate mounting.

- Standard NFPA square head, tie rod cylinder construction

- Pressure rating: 3000 PSI

- Standard fluid: Hydraulic oil

- Standard temperature: -20°F to + 200°F

- Seals: Buna N seals standard (Viton seals available - contact Centro for details)

- Ports are located in postion #1 as standard unless otherwise specified.

- Rod End Style: Small Male(KK2) Rod End Style

- Mount Description: Rod End Trunnion Mount (H71/MT1)

Port Type: NPT Stroke Length: 8"

"Our mission is to be regarded by our customers and our community as the best supplier of automation and control product solutions to industry."

Michael R Gallagher

Centro President