Centrifugal pumps are the most common types used in industrial and commercial applications. They can move large volumes of fluids, making them ideal for water treatment plants, oil refineries, and other high-demand environments. Centrifugal pumps come in various styles, including self-priming and submersible models. Centro offers a complete selection of centrifugal pumps available online, making it easy to find the right pump for your needs. Whether you're looking for a centrifugal water pump or a self-priming model, Centro has the perfect pump for your application.

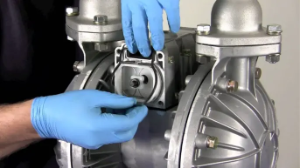

Pump Parts & Servicing products involves the maintenance, repair, and replacement of key pump components to ensure optimal performance and longevity. Regular servicing helps prevent breakdowns, reduces downtime, and extends the life of pumps in various industrial applications. It provides efficient operation, minimizes costly repairs, and maintains consistent fluid handling performance.

Sleeveline plug valves are highly reliable for precise fluid control in various industrial applications. These valves feature a cylindrical plug with a sleeve that rotates within the valve body, allowing for efficient flow regulation and tight shut-off. The sleeve provides excellent sealing properties, making sleeveline plug valves suitable for handling abrasive or viscous fluids, slurries, and corrosive chemicals. Their simple yet robust design minimizes maintenance requirements and ensures long-term durability, making them a cost-effective solution for critical fluid handling processes. Sleeveline plug valves are commonly used in industries such as oil and gas, chemical processing, and wastewater treatment, where dependable performance and resistance to wear are essential. With their versatile applications and reliable operation, sleeveline plug valves are vital in ensuring efficient and safe fluid control in various industrial settings.

High-performance butterfly valves are for managing fluid flow in tough industrial settings. They provide excellent sealing, durability, and easy operation, making them perfect for high-pressure and high-temperature settings. Widely used in industries like oil and gas, chemical processing, and power generation, these valves ensure efficient and reliable flow control. Their sturdy construction and advanced design, like double or triple offset configurations, offer top-notch performance and longevity. Check out our selection of high-performance butterfly valves below or contact us to speak to a product expert to help you with your selection.

PFA (perfluoroalkoxy) lined plug valves are indispensable assets in fluid handling systems, renowned for their exceptional chemical resistance and reliability. These valves feature a PFA lining that shields against corrosion and withstands aggressive chemicals, acids, and bases, ensuring longevity and efficiency in diverse industrial environments. With a plug design that rotates within the valve body, PFA-lined plug valves offer precise flow control and secure shut-off, even in demanding applications. Their robust construction and resistance to abrasion make them suitable for handling abrasive slurries, viscous fluids, and corrosive media. PFA-lined plug valves find extensive use in industries such as chemical processing, pharmaceuticals, and water treatment, where stringent quality standards and reliability are paramount. With their ability to deliver dependable performance and maintain product integrity, PFA-lined plug valves are trusted components for critical fluid handling processes.

PTFE (polytetrafluoroethylene) lined butterfly valves offer chemical resistance and reliability in fluid handling systems. Featuring a PTFE lining, these valves provide superior protection against corrosion and are compatible with a wide range of aggressive chemicals and high-purity fluids. The butterfly valve design ensures smooth flow control and tight shut-off, making them well-suited for applications where precise regulation of flow rates is essential. PTFE-lined butterfly valves find extensive use in industries such as chemical processing, water treatment, and pharmaceuticals, where maintaining product purity and preventing contamination is critical. Their durable construction and ability to withstand harsh operating conditions make them a trusted choice for ensuring efficient fluid handling and optimal performance in demanding environments.

Pumps are devices used to transfer liquids from one location to another. There are two main types of industrial pumps: positive-displacement pumps and nonpositive-displacement pumps. Positive-displacement pumps transfer liquid by enclosing a fixed volume and moving it through the system using seals or valves. These pumps are often used for pumping high-viscosity fluids. Nonpositive-displacement pumps, also known as centrifugal pumps, transfer liquid by circulating it through rotors called impellers. These pumps are typically used for high-capacity pumping applications such as water, solvents, chemicals, and light oils. Centro offers a wide range of pump types, including AOD pumps, lobe pumps, submersible pumps, hose/peristaltic pumps, metering pumps, progressive cavity pumps, sealless mag-drive pumps, hydraulic pumps, and pump control applications. You can learn more and make the right purchase for your needs by clicking on the provided links, or you can call Centro for expert guidance.

$1,980.64$2,536.00

Subject to factory lead times

$1,380.82$1,768.00

Subject to factory lead times

$3,779.30$4,839.00

Subject to factory lead times

$2,928.00$3,749.00

Subject to factory lead times

$1,868.17$2,392.00

Subject to factory lead times

$1,731.49$2,217.00

Subject to factory lead times

$2,691.35$3,446.00

Subject to factory lead times

$3,482.51$4,459.00

Subject to factory lead times

$990.32$1,268.00

Subject to factory lead times

$1,980.64$2,536.00

Subject to factory lead times

$1,380.82$1,768.00

Subject to factory lead times

$3,779.30$4,839.00

Subject to factory lead times

$2,928.00$3,749.00

Subject to factory lead times

$1,868.17$2,392.00

Subject to factory lead times

$1,731.49$2,217.00

Subject to factory lead times

$2,691.35$3,446.00

Subject to factory lead times

$3,482.51$4,459.00

Subject to factory lead times

$990.32$1,268.00

Subject to factory lead times