Miniature Shock Absorbers

Filters

Filters

228 RESULTS

content loaded

MPN:MC150H2

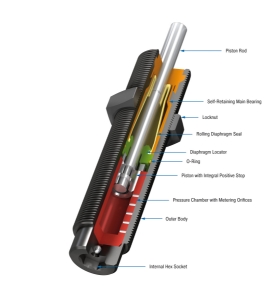

Tried-and-tested and durable: With a hermetically sealed rolling diaphragm in each absorber, the MC150 to MC600 product family is suitable for an exceptionally high lifetime of use with up to 25 million cycles. The rolling diaphragm technology perfected by ACE ensures complete separation of the damping fluid from the surrounding air. This makes it possible for direct installation in a pressure chamber to provide end stop damping in pneumatic cylinders up to approximately 100 psi (7 bar).

The rolling diaphragm delivers very low return forces for these maintenance-free, ready-to-install absorbers. An integrated positive stop and progressive energy capacities, with a wide range of effective weight, make these miniature shock absorbers a winner. Furthermore, the use of a side load adapter allows impact angles of up to 25°. Stainless steel options are available for greater environmental compatibility. Self-compensating shock absorbers react to changing energy conditions, without adjustment.

These self compensating miniature shock absorbers are capable of universal mounting even inside a cylinder. These shocks are ideal for use in multitude of applications including material handling equipment, packaging equipment, medium robotics and machine tools.

Tried-and-tested and durable: With a hermetically sealed rolling diaphragm in each absorber, the MC150 to MC600 product family is suitable for an exceptionally high lifetime of use with up to 25 million cycles. The rolling diaphragm technology perfected by ACE ensures complete separation of the damping fluid from the surrounding air. This makes it possible for direct installation in a pressure chamber to provide end stop damping in pneumatic cylinders up to approximately 100 psi (7 bar).

The rolling diaphragm delivers very low return forces for these maintenance-free, ready-to-install absorbers. An integrated positive stop and progressive energy capacities, with a wide range of effective weight, make these miniature shock absorbers a winner. Furthermore, the use of a side load adapter allows impact angles of up to 25°. Stainless steel options are available for greater environmental compatibility. Self-compensating shock absorbers react to changing energy conditions, without adjustment.

These self compensating miniature shock absorbers are capable of universal mounting even inside a cylinder. These shocks are ideal for use in multitude of applications including material handling equipment, packaging equipment, medium robotics and machine tools.

$85.92

Loginto your account

In Stock (16)

Ships within 1 business day

MPN:MC150H3

Tried-and-tested and durable: With a hermetically sealed rolling diaphragm in each absorber, the MC150 to MC600 product family is suitable for an exceptionally high lifetime of use with up to 25 million cycles. The rolling diaphragm technology perfected by ACE ensures complete separation of the damping fluid from the surrounding air. This makes it possible for direct installation in a pressure chamber to provide end stop damping in pneumatic cylinders up to approximately 100 psi (7 bar).

The rolling diaphragm delivers very low return forces for these maintenance-free, ready-to-install absorbers. An integrated positive stop and progressive energy capacities, with a wide range of effective weight, make these miniature shock absorbers a winner. Furthermore, the use of a side load adapter allows impact angles of up to 25°. Stainless steel options are available for greater environmental compatibility. Self-compensating shock absorbers react to changing energy conditions, without adjustment.

These self compensating miniature shock absorbers are capable of universal mounting even inside a cylinder. These shocks are ideal for use in multitude of applications including material handling equipment, packaging equipment, medium robotics and machine tools.

Tried-and-tested and durable: With a hermetically sealed rolling diaphragm in each absorber, the MC150 to MC600 product family is suitable for an exceptionally high lifetime of use with up to 25 million cycles. The rolling diaphragm technology perfected by ACE ensures complete separation of the damping fluid from the surrounding air. This makes it possible for direct installation in a pressure chamber to provide end stop damping in pneumatic cylinders up to approximately 100 psi (7 bar).

The rolling diaphragm delivers very low return forces for these maintenance-free, ready-to-install absorbers. An integrated positive stop and progressive energy capacities, with a wide range of effective weight, make these miniature shock absorbers a winner. Furthermore, the use of a side load adapter allows impact angles of up to 25°. Stainless steel options are available for greater environmental compatibility. Self-compensating shock absorbers react to changing energy conditions, without adjustment.

These self compensating miniature shock absorbers are capable of universal mounting even inside a cylinder. These shocks are ideal for use in multitude of applications including material handling equipment, packaging equipment, medium robotics and machine tools.

Requires Quote

Available for Purchase

Subject to factory lead times

MPN:MC150M

Tried-and-tested and durable: With a hermetically sealed rolling diaphragm in each absorber, the MC150 to MC600 product family is suitable for an exceptionally high lifetime of use with up to 25 million cycles. The rolling diaphragm technology perfected by ACE ensures complete separation of the damping fluid from the surrounding air. This makes it possible for direct installation in a pressure chamber to provide end stop damping in pneumatic cylinders up to approximately 100 psi (7 bar).

The rolling diaphragm delivers very low return forces for these maintenance-free, ready-to-install absorbers. An integrated positive stop and progressive energy capacities, with a wide range of effective weight, make these miniature shock absorbers a winner. Furthermore, the use of a side load adapter allows impact angles of up to 25°. Stainless steel options are available for greater environmental compatibility. Self-compensating shock absorbers react to changing energy conditions, without adjustment.

These self compensating miniature shock absorbers are capable of universal mounting even inside a cylinder. These shocks are ideal for use in multitude of applications including material handling equipment, packaging equipment, medium robotics and machine tools.

Tried-and-tested and durable: With a hermetically sealed rolling diaphragm in each absorber, the MC150 to MC600 product family is suitable for an exceptionally high lifetime of use with up to 25 million cycles. The rolling diaphragm technology perfected by ACE ensures complete separation of the damping fluid from the surrounding air. This makes it possible for direct installation in a pressure chamber to provide end stop damping in pneumatic cylinders up to approximately 100 psi (7 bar).

The rolling diaphragm delivers very low return forces for these maintenance-free, ready-to-install absorbers. An integrated positive stop and progressive energy capacities, with a wide range of effective weight, make these miniature shock absorbers a winner. Furthermore, the use of a side load adapter allows impact angles of up to 25°. Stainless steel options are available for greater environmental compatibility. Self-compensating shock absorbers react to changing energy conditions, without adjustment.

These self compensating miniature shock absorbers are capable of universal mounting even inside a cylinder. These shocks are ideal for use in multitude of applications including material handling equipment, packaging equipment, medium robotics and machine tools.

$72.39

Loginto your account

Low Stock (1)

Ships within 1 business day

MPN:MC150M-V4A

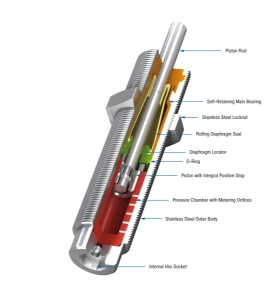

Brilliant in every respect: These high performance stainless steel miniature shock absorbers are based on the MC150 to MC600 product family and its proven damping technology. This means that these special absorbers offer all of the benefits of the standard units such as the ACE rolling diaphragm technology which delivers maximum service life and direct installation in a pressure chamber with up to approx. 100 psi (7 bar).

Thanks to perfectly progressive maximum energy absorption and effective weight potential, their use is augmented even further by the stainless steel outer body and a complete range of stainless accessories (AISI 316L). Self-compensating shock absorbers react to changing energy conditions, without adjustment.

These self-compensating miniature stainless steel shock absorbers are used in medical and electro-technology, as well as marine, packaging, and chemical applications. Shocks can be filled with food-grade oil for food processing applications.

Brilliant in every respect: These high performance stainless steel miniature shock absorbers are based on the MC150 to MC600 product family and its proven damping technology. This means that these special absorbers offer all of the benefits of the standard units such as the ACE rolling diaphragm technology which delivers maximum service life and direct installation in a pressure chamber with up to approx. 100 psi (7 bar).

Thanks to perfectly progressive maximum energy absorption and effective weight potential, their use is augmented even further by the stainless steel outer body and a complete range of stainless accessories (AISI 316L). Self-compensating shock absorbers react to changing energy conditions, without adjustment.

These self-compensating miniature stainless steel shock absorbers are used in medical and electro-technology, as well as marine, packaging, and chemical applications. Shocks can be filled with food-grade oil for food processing applications.

Requires Quote

Available for Purchase

Subject to factory lead times

MPN:MC150MH

Tried-and-tested and durable: With a hermetically sealed rolling diaphragm in each absorber, the MC150 to MC600 product family is suitable for an exceptionally high lifetime of use with up to 25 million cycles. The rolling diaphragm technology perfected by ACE ensures complete separation of the damping fluid from the surrounding air. This makes it possible for direct installation in a pressure chamber to provide end stop damping in pneumatic cylinders up to approximately 100 psi (7 bar).

The rolling diaphragm delivers very low return forces for these maintenance-free, ready-to-install absorbers. An integrated positive stop and progressive energy capacities, with a wide range of effective weight, make these miniature shock absorbers a winner. Furthermore, the use of a side load adapter allows impact angles of up to 25°. Stainless steel options are available for greater environmental compatibility. Self-compensating shock absorbers react to changing energy conditions, without adjustment.

These self compensating miniature shock absorbers are capable of universal mounting even inside a cylinder. These shocks are ideal for use in multitude of applications including material handling equipment, packaging equipment, medium robotics and machine tools.

Tried-and-tested and durable: With a hermetically sealed rolling diaphragm in each absorber, the MC150 to MC600 product family is suitable for an exceptionally high lifetime of use with up to 25 million cycles. The rolling diaphragm technology perfected by ACE ensures complete separation of the damping fluid from the surrounding air. This makes it possible for direct installation in a pressure chamber to provide end stop damping in pneumatic cylinders up to approximately 100 psi (7 bar).

The rolling diaphragm delivers very low return forces for these maintenance-free, ready-to-install absorbers. An integrated positive stop and progressive energy capacities, with a wide range of effective weight, make these miniature shock absorbers a winner. Furthermore, the use of a side load adapter allows impact angles of up to 25°. Stainless steel options are available for greater environmental compatibility. Self-compensating shock absorbers react to changing energy conditions, without adjustment.

These self compensating miniature shock absorbers are capable of universal mounting even inside a cylinder. These shocks are ideal for use in multitude of applications including material handling equipment, packaging equipment, medium robotics and machine tools.

Sale Price:

$72.20$78.51

Loginto your account

In Stock (10)

Ships within 1 business day

MPN:MC150MH-V4A

Brilliant in every respect: These high performance stainless steel miniature shock absorbers are based on the MC150 to MC600 product family and its proven damping technology. This means that these special absorbers offer all of the benefits of the standard units such as the ACE rolling diaphragm technology which delivers maximum service life and direct installation in a pressure chamber with up to approx. 100 psi (7 bar).

Thanks to perfectly progressive maximum energy absorption and effective weight potential, their use is augmented even further by the stainless steel outer body and a complete range of stainless accessories (AISI 316L). Self-compensating shock absorbers react to changing energy conditions, without adjustment.

These self-compensating miniature stainless steel shock absorbers are used in medical and electro-technology, as well as marine, packaging, and chemical applications. Shocks can be filled with food-grade oil for food processing applications.

Brilliant in every respect: These high performance stainless steel miniature shock absorbers are based on the MC150 to MC600 product family and its proven damping technology. This means that these special absorbers offer all of the benefits of the standard units such as the ACE rolling diaphragm technology which delivers maximum service life and direct installation in a pressure chamber with up to approx. 100 psi (7 bar).

Thanks to perfectly progressive maximum energy absorption and effective weight potential, their use is augmented even further by the stainless steel outer body and a complete range of stainless accessories (AISI 316L). Self-compensating shock absorbers react to changing energy conditions, without adjustment.

These self-compensating miniature stainless steel shock absorbers are used in medical and electro-technology, as well as marine, packaging, and chemical applications. Shocks can be filled with food-grade oil for food processing applications.

Requires Quote

Available for Purchase

Subject to factory lead times

MPN:MC150MH2

Tried-and-tested and durable: With a hermetically sealed rolling diaphragm in each absorber, the MC150 to MC600 product family is suitable for an exceptionally high lifetime of use with up to 25 million cycles. The rolling diaphragm technology perfected by ACE ensures complete separation of the damping fluid from the surrounding air. This makes it possible for direct installation in a pressure chamber to provide end stop damping in pneumatic cylinders up to approximately 100 psi (7 bar).

The rolling diaphragm delivers very low return forces for these maintenance-free, ready-to-install absorbers. An integrated positive stop and progressive energy capacities, with a wide range of effective weight, make these miniature shock absorbers a winner. Furthermore, the use of a side load adapter allows impact angles of up to 25°. Stainless steel options are available for greater environmental compatibility. Self-compensating shock absorbers react to changing energy conditions, without adjustment.

These self compensating miniature shock absorbers are capable of universal mounting even inside a cylinder. These shocks are ideal for use in multitude of applications including material handling equipment, packaging equipment, medium robotics and machine tools.

Tried-and-tested and durable: With a hermetically sealed rolling diaphragm in each absorber, the MC150 to MC600 product family is suitable for an exceptionally high lifetime of use with up to 25 million cycles. The rolling diaphragm technology perfected by ACE ensures complete separation of the damping fluid from the surrounding air. This makes it possible for direct installation in a pressure chamber to provide end stop damping in pneumatic cylinders up to approximately 100 psi (7 bar).

The rolling diaphragm delivers very low return forces for these maintenance-free, ready-to-install absorbers. An integrated positive stop and progressive energy capacities, with a wide range of effective weight, make these miniature shock absorbers a winner. Furthermore, the use of a side load adapter allows impact angles of up to 25°. Stainless steel options are available for greater environmental compatibility. Self-compensating shock absorbers react to changing energy conditions, without adjustment.

These self compensating miniature shock absorbers are capable of universal mounting even inside a cylinder. These shocks are ideal for use in multitude of applications including material handling equipment, packaging equipment, medium robotics and machine tools.

$85.90

Loginto your account

Available for Purchase

Subject to factory lead times

MPN:MC150MH2-V4A

Brilliant in every respect: These high performance stainless steel miniature shock absorbers are based on the MC150 to MC600 product family and its proven damping technology. This means that these special absorbers offer all of the benefits of the standard units such as the ACE rolling diaphragm technology which delivers maximum service life and direct installation in a pressure chamber with up to approx. 100 psi (7 bar).

Thanks to perfectly progressive maximum energy absorption and effective weight potential, their use is augmented even further by the stainless steel outer body and a complete range of stainless accessories (AISI 316L). Self-compensating shock absorbers react to changing energy conditions, without adjustment.

These self-compensating miniature stainless steel shock absorbers are used in medical and electro-technology, as well as marine, packaging, and chemical applications. Shocks can be filled with food-grade oil for food processing applications.

Brilliant in every respect: These high performance stainless steel miniature shock absorbers are based on the MC150 to MC600 product family and its proven damping technology. This means that these special absorbers offer all of the benefits of the standard units such as the ACE rolling diaphragm technology which delivers maximum service life and direct installation in a pressure chamber with up to approx. 100 psi (7 bar).

Thanks to perfectly progressive maximum energy absorption and effective weight potential, their use is augmented even further by the stainless steel outer body and a complete range of stainless accessories (AISI 316L). Self-compensating shock absorbers react to changing energy conditions, without adjustment.

These self-compensating miniature stainless steel shock absorbers are used in medical and electro-technology, as well as marine, packaging, and chemical applications. Shocks can be filled with food-grade oil for food processing applications.

Requires Quote

Available for Purchase

Subject to factory lead times

MPN:MC150MH3

Tried-and-tested and durable: With a hermetically sealed rolling diaphragm in each absorber, the MC150 to MC600 product family is suitable for an exceptionally high lifetime of use with up to 25 million cycles. The rolling diaphragm technology perfected by ACE ensures complete separation of the damping fluid from the surrounding air. This makes it possible for direct installation in a pressure chamber to provide end stop damping in pneumatic cylinders up to approximately 100 psi (7 bar).

The rolling diaphragm delivers very low return forces for these maintenance-free, ready-to-install absorbers. An integrated positive stop and progressive energy capacities, with a wide range of effective weight, make these miniature shock absorbers a winner. Furthermore, the use of a side load adapter allows impact angles of up to 25°. Stainless steel options are available for greater environmental compatibility. Self-compensating shock absorbers react to changing energy conditions, without adjustment.

These self compensating miniature shock absorbers are capable of universal mounting even inside a cylinder. These shocks are ideal for use in multitude of applications including material handling equipment, packaging equipment, medium robotics and machine tools.

Tried-and-tested and durable: With a hermetically sealed rolling diaphragm in each absorber, the MC150 to MC600 product family is suitable for an exceptionally high lifetime of use with up to 25 million cycles. The rolling diaphragm technology perfected by ACE ensures complete separation of the damping fluid from the surrounding air. This makes it possible for direct installation in a pressure chamber to provide end stop damping in pneumatic cylinders up to approximately 100 psi (7 bar).

The rolling diaphragm delivers very low return forces for these maintenance-free, ready-to-install absorbers. An integrated positive stop and progressive energy capacities, with a wide range of effective weight, make these miniature shock absorbers a winner. Furthermore, the use of a side load adapter allows impact angles of up to 25°. Stainless steel options are available for greater environmental compatibility. Self-compensating shock absorbers react to changing energy conditions, without adjustment.

These self compensating miniature shock absorbers are capable of universal mounting even inside a cylinder. These shocks are ideal for use in multitude of applications including material handling equipment, packaging equipment, medium robotics and machine tools.

Requires Quote

Available for Purchase

Subject to factory lead times

MPN:MC150H2

Tried-and-tested and durable: With a hermetically sealed rolling diaphragm in each absorber, the MC150 to MC600 product family is suitable for an exceptionally high lifetime of use with up to 25 million cycles. The rolling diaphragm technology perfected by ACE ensures complete separation of the damping fluid from the surrounding air. This makes it possible for direct installation in a pressure chamber to provide end stop damping in pneumatic cylinders up to approximately 100 psi (7 bar).

The rolling diaphragm delivers very low return forces for these maintenance-free, ready-to-install absorbers. An integrated positive stop and progressive energy capacities, with a wide range of effective weight, make these miniature shock absorbers a winner. Furthermore, the use of a side load adapter allows impact angles of up to 25°. Stainless steel options are available for greater environmental compatibility. Self-compensating shock absorbers react to changing energy conditions, without adjustment.

These self compensating miniature shock absorbers are capable of universal mounting even inside a cylinder. These shocks are ideal for use in multitude of applications including material handling equipment, packaging equipment, medium robotics and machine tools.

Tried-and-tested and durable: With a hermetically sealed rolling diaphragm in each absorber, the MC150 to MC600 product family is suitable for an exceptionally high lifetime of use with up to 25 million cycles. The rolling diaphragm technology perfected by ACE ensures complete separation of the damping fluid from the surrounding air. This makes it possible for direct installation in a pressure chamber to provide end stop damping in pneumatic cylinders up to approximately 100 psi (7 bar).

The rolling diaphragm delivers very low return forces for these maintenance-free, ready-to-install absorbers. An integrated positive stop and progressive energy capacities, with a wide range of effective weight, make these miniature shock absorbers a winner. Furthermore, the use of a side load adapter allows impact angles of up to 25°. Stainless steel options are available for greater environmental compatibility. Self-compensating shock absorbers react to changing energy conditions, without adjustment.

These self compensating miniature shock absorbers are capable of universal mounting even inside a cylinder. These shocks are ideal for use in multitude of applications including material handling equipment, packaging equipment, medium robotics and machine tools.

$85.92

Loginto your account

In Stock (16)

Ships within 1 business day

MPN:MC150H3

Tried-and-tested and durable: With a hermetically sealed rolling diaphragm in each absorber, the MC150 to MC600 product family is suitable for an exceptionally high lifetime of use with up to 25 million cycles. The rolling diaphragm technology perfected by ACE ensures complete separation of the damping fluid from the surrounding air. This makes it possible for direct installation in a pressure chamber to provide end stop damping in pneumatic cylinders up to approximately 100 psi (7 bar).

The rolling diaphragm delivers very low return forces for these maintenance-free, ready-to-install absorbers. An integrated positive stop and progressive energy capacities, with a wide range of effective weight, make these miniature shock absorbers a winner. Furthermore, the use of a side load adapter allows impact angles of up to 25°. Stainless steel options are available for greater environmental compatibility. Self-compensating shock absorbers react to changing energy conditions, without adjustment.

These self compensating miniature shock absorbers are capable of universal mounting even inside a cylinder. These shocks are ideal for use in multitude of applications including material handling equipment, packaging equipment, medium robotics and machine tools.

Tried-and-tested and durable: With a hermetically sealed rolling diaphragm in each absorber, the MC150 to MC600 product family is suitable for an exceptionally high lifetime of use with up to 25 million cycles. The rolling diaphragm technology perfected by ACE ensures complete separation of the damping fluid from the surrounding air. This makes it possible for direct installation in a pressure chamber to provide end stop damping in pneumatic cylinders up to approximately 100 psi (7 bar).

The rolling diaphragm delivers very low return forces for these maintenance-free, ready-to-install absorbers. An integrated positive stop and progressive energy capacities, with a wide range of effective weight, make these miniature shock absorbers a winner. Furthermore, the use of a side load adapter allows impact angles of up to 25°. Stainless steel options are available for greater environmental compatibility. Self-compensating shock absorbers react to changing energy conditions, without adjustment.

These self compensating miniature shock absorbers are capable of universal mounting even inside a cylinder. These shocks are ideal for use in multitude of applications including material handling equipment, packaging equipment, medium robotics and machine tools.

Requires Quote

Available for Purchase

Subject to factory lead times

MPN:MC150M

Tried-and-tested and durable: With a hermetically sealed rolling diaphragm in each absorber, the MC150 to MC600 product family is suitable for an exceptionally high lifetime of use with up to 25 million cycles. The rolling diaphragm technology perfected by ACE ensures complete separation of the damping fluid from the surrounding air. This makes it possible for direct installation in a pressure chamber to provide end stop damping in pneumatic cylinders up to approximately 100 psi (7 bar).

The rolling diaphragm delivers very low return forces for these maintenance-free, ready-to-install absorbers. An integrated positive stop and progressive energy capacities, with a wide range of effective weight, make these miniature shock absorbers a winner. Furthermore, the use of a side load adapter allows impact angles of up to 25°. Stainless steel options are available for greater environmental compatibility. Self-compensating shock absorbers react to changing energy conditions, without adjustment.

These self compensating miniature shock absorbers are capable of universal mounting even inside a cylinder. These shocks are ideal for use in multitude of applications including material handling equipment, packaging equipment, medium robotics and machine tools.

Tried-and-tested and durable: With a hermetically sealed rolling diaphragm in each absorber, the MC150 to MC600 product family is suitable for an exceptionally high lifetime of use with up to 25 million cycles. The rolling diaphragm technology perfected by ACE ensures complete separation of the damping fluid from the surrounding air. This makes it possible for direct installation in a pressure chamber to provide end stop damping in pneumatic cylinders up to approximately 100 psi (7 bar).

The rolling diaphragm delivers very low return forces for these maintenance-free, ready-to-install absorbers. An integrated positive stop and progressive energy capacities, with a wide range of effective weight, make these miniature shock absorbers a winner. Furthermore, the use of a side load adapter allows impact angles of up to 25°. Stainless steel options are available for greater environmental compatibility. Self-compensating shock absorbers react to changing energy conditions, without adjustment.

These self compensating miniature shock absorbers are capable of universal mounting even inside a cylinder. These shocks are ideal for use in multitude of applications including material handling equipment, packaging equipment, medium robotics and machine tools.

$72.39

Loginto your account

Low Stock (1)

Ships within 1 business day

MPN:MC150M-V4A

Brilliant in every respect: These high performance stainless steel miniature shock absorbers are based on the MC150 to MC600 product family and its proven damping technology. This means that these special absorbers offer all of the benefits of the standard units such as the ACE rolling diaphragm technology which delivers maximum service life and direct installation in a pressure chamber with up to approx. 100 psi (7 bar).

Thanks to perfectly progressive maximum energy absorption and effective weight potential, their use is augmented even further by the stainless steel outer body and a complete range of stainless accessories (AISI 316L). Self-compensating shock absorbers react to changing energy conditions, without adjustment.

These self-compensating miniature stainless steel shock absorbers are used in medical and electro-technology, as well as marine, packaging, and chemical applications. Shocks can be filled with food-grade oil for food processing applications.

Brilliant in every respect: These high performance stainless steel miniature shock absorbers are based on the MC150 to MC600 product family and its proven damping technology. This means that these special absorbers offer all of the benefits of the standard units such as the ACE rolling diaphragm technology which delivers maximum service life and direct installation in a pressure chamber with up to approx. 100 psi (7 bar).

Thanks to perfectly progressive maximum energy absorption and effective weight potential, their use is augmented even further by the stainless steel outer body and a complete range of stainless accessories (AISI 316L). Self-compensating shock absorbers react to changing energy conditions, without adjustment.

These self-compensating miniature stainless steel shock absorbers are used in medical and electro-technology, as well as marine, packaging, and chemical applications. Shocks can be filled with food-grade oil for food processing applications.

Requires Quote

Available for Purchase

Subject to factory lead times

MPN:MC150MH

Tried-and-tested and durable: With a hermetically sealed rolling diaphragm in each absorber, the MC150 to MC600 product family is suitable for an exceptionally high lifetime of use with up to 25 million cycles. The rolling diaphragm technology perfected by ACE ensures complete separation of the damping fluid from the surrounding air. This makes it possible for direct installation in a pressure chamber to provide end stop damping in pneumatic cylinders up to approximately 100 psi (7 bar).

The rolling diaphragm delivers very low return forces for these maintenance-free, ready-to-install absorbers. An integrated positive stop and progressive energy capacities, with a wide range of effective weight, make these miniature shock absorbers a winner. Furthermore, the use of a side load adapter allows impact angles of up to 25°. Stainless steel options are available for greater environmental compatibility. Self-compensating shock absorbers react to changing energy conditions, without adjustment.

These self compensating miniature shock absorbers are capable of universal mounting even inside a cylinder. These shocks are ideal for use in multitude of applications including material handling equipment, packaging equipment, medium robotics and machine tools.

Tried-and-tested and durable: With a hermetically sealed rolling diaphragm in each absorber, the MC150 to MC600 product family is suitable for an exceptionally high lifetime of use with up to 25 million cycles. The rolling diaphragm technology perfected by ACE ensures complete separation of the damping fluid from the surrounding air. This makes it possible for direct installation in a pressure chamber to provide end stop damping in pneumatic cylinders up to approximately 100 psi (7 bar).

The rolling diaphragm delivers very low return forces for these maintenance-free, ready-to-install absorbers. An integrated positive stop and progressive energy capacities, with a wide range of effective weight, make these miniature shock absorbers a winner. Furthermore, the use of a side load adapter allows impact angles of up to 25°. Stainless steel options are available for greater environmental compatibility. Self-compensating shock absorbers react to changing energy conditions, without adjustment.

These self compensating miniature shock absorbers are capable of universal mounting even inside a cylinder. These shocks are ideal for use in multitude of applications including material handling equipment, packaging equipment, medium robotics and machine tools.

Sale Price:

$72.20$78.51

Loginto your account

In Stock (10)

Ships within 1 business day

MPN:MC150MH-V4A

Brilliant in every respect: These high performance stainless steel miniature shock absorbers are based on the MC150 to MC600 product family and its proven damping technology. This means that these special absorbers offer all of the benefits of the standard units such as the ACE rolling diaphragm technology which delivers maximum service life and direct installation in a pressure chamber with up to approx. 100 psi (7 bar).

Thanks to perfectly progressive maximum energy absorption and effective weight potential, their use is augmented even further by the stainless steel outer body and a complete range of stainless accessories (AISI 316L). Self-compensating shock absorbers react to changing energy conditions, without adjustment.

These self-compensating miniature stainless steel shock absorbers are used in medical and electro-technology, as well as marine, packaging, and chemical applications. Shocks can be filled with food-grade oil for food processing applications.

Brilliant in every respect: These high performance stainless steel miniature shock absorbers are based on the MC150 to MC600 product family and its proven damping technology. This means that these special absorbers offer all of the benefits of the standard units such as the ACE rolling diaphragm technology which delivers maximum service life and direct installation in a pressure chamber with up to approx. 100 psi (7 bar).

Thanks to perfectly progressive maximum energy absorption and effective weight potential, their use is augmented even further by the stainless steel outer body and a complete range of stainless accessories (AISI 316L). Self-compensating shock absorbers react to changing energy conditions, without adjustment.

These self-compensating miniature stainless steel shock absorbers are used in medical and electro-technology, as well as marine, packaging, and chemical applications. Shocks can be filled with food-grade oil for food processing applications.

Requires Quote

Available for Purchase

Subject to factory lead times

MPN:MC150MH2

Tried-and-tested and durable: With a hermetically sealed rolling diaphragm in each absorber, the MC150 to MC600 product family is suitable for an exceptionally high lifetime of use with up to 25 million cycles. The rolling diaphragm technology perfected by ACE ensures complete separation of the damping fluid from the surrounding air. This makes it possible for direct installation in a pressure chamber to provide end stop damping in pneumatic cylinders up to approximately 100 psi (7 bar).

The rolling diaphragm delivers very low return forces for these maintenance-free, ready-to-install absorbers. An integrated positive stop and progressive energy capacities, with a wide range of effective weight, make these miniature shock absorbers a winner. Furthermore, the use of a side load adapter allows impact angles of up to 25°. Stainless steel options are available for greater environmental compatibility. Self-compensating shock absorbers react to changing energy conditions, without adjustment.

These self compensating miniature shock absorbers are capable of universal mounting even inside a cylinder. These shocks are ideal for use in multitude of applications including material handling equipment, packaging equipment, medium robotics and machine tools.

Tried-and-tested and durable: With a hermetically sealed rolling diaphragm in each absorber, the MC150 to MC600 product family is suitable for an exceptionally high lifetime of use with up to 25 million cycles. The rolling diaphragm technology perfected by ACE ensures complete separation of the damping fluid from the surrounding air. This makes it possible for direct installation in a pressure chamber to provide end stop damping in pneumatic cylinders up to approximately 100 psi (7 bar).

The rolling diaphragm delivers very low return forces for these maintenance-free, ready-to-install absorbers. An integrated positive stop and progressive energy capacities, with a wide range of effective weight, make these miniature shock absorbers a winner. Furthermore, the use of a side load adapter allows impact angles of up to 25°. Stainless steel options are available for greater environmental compatibility. Self-compensating shock absorbers react to changing energy conditions, without adjustment.

These self compensating miniature shock absorbers are capable of universal mounting even inside a cylinder. These shocks are ideal for use in multitude of applications including material handling equipment, packaging equipment, medium robotics and machine tools.

$85.90

Loginto your account

Available for Purchase

Subject to factory lead times

MPN:MC150MH2-V4A

Brilliant in every respect: These high performance stainless steel miniature shock absorbers are based on the MC150 to MC600 product family and its proven damping technology. This means that these special absorbers offer all of the benefits of the standard units such as the ACE rolling diaphragm technology which delivers maximum service life and direct installation in a pressure chamber with up to approx. 100 psi (7 bar).

Thanks to perfectly progressive maximum energy absorption and effective weight potential, their use is augmented even further by the stainless steel outer body and a complete range of stainless accessories (AISI 316L). Self-compensating shock absorbers react to changing energy conditions, without adjustment.

These self-compensating miniature stainless steel shock absorbers are used in medical and electro-technology, as well as marine, packaging, and chemical applications. Shocks can be filled with food-grade oil for food processing applications.

Brilliant in every respect: These high performance stainless steel miniature shock absorbers are based on the MC150 to MC600 product family and its proven damping technology. This means that these special absorbers offer all of the benefits of the standard units such as the ACE rolling diaphragm technology which delivers maximum service life and direct installation in a pressure chamber with up to approx. 100 psi (7 bar).

Thanks to perfectly progressive maximum energy absorption and effective weight potential, their use is augmented even further by the stainless steel outer body and a complete range of stainless accessories (AISI 316L). Self-compensating shock absorbers react to changing energy conditions, without adjustment.

These self-compensating miniature stainless steel shock absorbers are used in medical and electro-technology, as well as marine, packaging, and chemical applications. Shocks can be filled with food-grade oil for food processing applications.

Requires Quote

Available for Purchase

Subject to factory lead times

MPN:MC150MH3

Tried-and-tested and durable: With a hermetically sealed rolling diaphragm in each absorber, the MC150 to MC600 product family is suitable for an exceptionally high lifetime of use with up to 25 million cycles. The rolling diaphragm technology perfected by ACE ensures complete separation of the damping fluid from the surrounding air. This makes it possible for direct installation in a pressure chamber to provide end stop damping in pneumatic cylinders up to approximately 100 psi (7 bar).

The rolling diaphragm delivers very low return forces for these maintenance-free, ready-to-install absorbers. An integrated positive stop and progressive energy capacities, with a wide range of effective weight, make these miniature shock absorbers a winner. Furthermore, the use of a side load adapter allows impact angles of up to 25°. Stainless steel options are available for greater environmental compatibility. Self-compensating shock absorbers react to changing energy conditions, without adjustment.

These self compensating miniature shock absorbers are capable of universal mounting even inside a cylinder. These shocks are ideal for use in multitude of applications including material handling equipment, packaging equipment, medium robotics and machine tools.

Tried-and-tested and durable: With a hermetically sealed rolling diaphragm in each absorber, the MC150 to MC600 product family is suitable for an exceptionally high lifetime of use with up to 25 million cycles. The rolling diaphragm technology perfected by ACE ensures complete separation of the damping fluid from the surrounding air. This makes it possible for direct installation in a pressure chamber to provide end stop damping in pneumatic cylinders up to approximately 100 psi (7 bar).

The rolling diaphragm delivers very low return forces for these maintenance-free, ready-to-install absorbers. An integrated positive stop and progressive energy capacities, with a wide range of effective weight, make these miniature shock absorbers a winner. Furthermore, the use of a side load adapter allows impact angles of up to 25°. Stainless steel options are available for greater environmental compatibility. Self-compensating shock absorbers react to changing energy conditions, without adjustment.

These self compensating miniature shock absorbers are capable of universal mounting even inside a cylinder. These shocks are ideal for use in multitude of applications including material handling equipment, packaging equipment, medium robotics and machine tools.

Requires Quote

Available for Purchase

Subject to factory lead times