Motor Control

Centro carries a complete selection of motor control products available to purchase online. Industrial motor controllers are devices that regulate the speed and torque of an electric motor. VFDs control the sp...

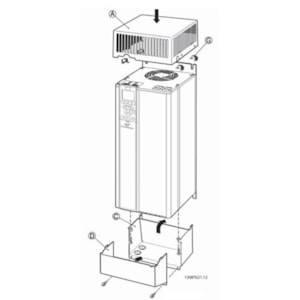

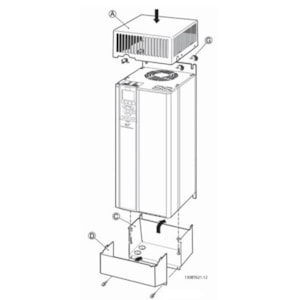

Variable Frequency Drives (VFDs) are electronic devices used to control the speed and torque of electric motors by varying the frequency and voltage of the supplied power. They are widely used in industrial and commercial applications to optimize energy consumption, improve motor control, and enhance system performance. VFDs enable precise speed control, soft starting, and acceleration, reducing mechanical stress and energy waste. They provide flexibility in adjusting motor speed to match specific process requirements, resulting in energy savings and increased efficiency. With features like built-in protection, advanced control algorithms, and communication capabilities, VFDs offer reliable and efficient motor control solutions for various applications.

Configured drives and control systems offer turnkey motor control solutions tailored to specific industrial applications, combining variable frequency drives (VFDs), soft starters, PLCs, and HMIs into pre-engineered, panel-mounted packages. Designed for seamless integration, these systems simplify installation, reduce commissioning time, and ensure precise control of pumps, fans, conveyors, and complex machinery. With customizable features like communication protocols, enclosure ratings, and application-specific logic, configured drives and control systems deliver reliable, efficient, and scalable performance in demanding automation environments.

Manual starters, also known as motor starters, control the operation of electric motors manually. These devices combine switches, thermal overload relays, and protection elements in a single unit to start, stop, and safeguard motors from overcurrents and overheating. Widely used in industrial settings like manufacturing and HVAC systems, manual starters offer robust performance and essential safety features for precise motor control. Explore our manual starter options below or contact us to speak to a product expert.

Contactors are electrically-operated switches used to control the flow of electricity in a circuit. They are essential components in electrical systems, including those for motors, heating, lighting, and power distribution. Contactors can handle higher current loads compared to regular switches, making them important in industrial and commercial settings. Their ability to provide safe and reliable control of electrical circuits makes them crucial in applications that require frequent switching operations and where remote control is necessary. Browse our selection of contactors below or contact us to speak with a product expert.

Control relays are electrical devices that control and switch electrical circuits in industrial automation and control systems. These relays act as electromechanical switches, allowing a low-power control signal to control a higher-power circuit. Control relays are commonly used to control motors, solenoids, lights, and other electrical loads. They provide reliable and efficient control by isolating the control circuit from the higher-voltage or higher-current circuits. Control relays are available in various configurations, such as electromechanical and solid-state relays, offering different features and capabilities. They play a crucial role in automating processes, ensuring proper sequencing, and enhancing the safety and reliability of control systems.

Soft starters are electrical devices used to control the acceleration and deceleration of electric motors by regulating the voltage applied during startup. Unlike traditional direct-on-line starters, soft starters gradually ramp up motor speed, reducing mechanical stress and current surges. Browse our selection below or contact us to speak with a product expert.

Motor control parts are used to manage and regulate the operation of electric motors in various industrial and commercial applications. They include devices such as contactors, relays, motor starters, and variable frequency drives (VFDs), which control motor speed, direction, and protection. These parts are for smooth motor operation, energy efficiency, and safety in machinery, HVAC systems, and automation equipment. Browse our selection below or contact us to speak with a product expert.

Contactor accessories are supplementary components used to enhance the functionality and performance of electrical contactors in industrial and commercial applications. They include items such as auxiliary contacts, overload relays, interlocks, and surge suppressors, which extend the capabilities of contactors for controlling electrical circuits. These accessories are essential for ensuring reliable operation, protection, and flexibility in motor control, HVAC systems, and other electrical equipment. Browse our selection below or contact us to speak to a product expert.

Overload relays are protective devices used to safeguard electric motors from overheating and damage caused by excessive current. They monitor motor currents and automatically disconnect the motor from the power supply if it exceeds preset limits, preventing burnout and enhancing operational safety. Browse our selection below or contact us to speak to a product expert.

Universal motor controllers are tools for managing and optimizing the performance of various electric motors. They offer precise control over speed, torque, and direction, which boosts efficiency and reliability in industrial applications. Universal motor controllers work with AC, DC, and servo motors and are commonly used in manufacturing, automation, and HVAC systems. With features like programmable settings, overload protection, and energy-saving options, they help businesses improve operational control, cut energy costs, and extend the lifespan of motor-driven equipment. Check out our universal motor controllers selection below or contact us to speak with a product expert.

Motor starters are for safely starting and stopping electric motors, particularly in industrial and commercial industry. They regulate the power sent to the motor, ensuring it ramps up to full speed without drawing too much current. This prevents potential damage to the motor and other electrical components. Motor starters come with built-in overload protection, adding an extra layer of safety by automatically shutting down the motor if it overheats or experiences a fault. Easy to install and operate, these devices are crucial for maintaining the longevity and reliability of your motor-driven equipment. Explore our range of motor starters below or contact us to speak with a product expert.

Line reactors and output filters protect variable frequency drives (VFDs) and connected motors by reducing harmonic distortion, voltage spikes, and electrical noise in industrial power systems. Line reactors are installed on the input side to improve power quality and extend drive life, while output filters condition the waveform on the motor side to prevent insulation damage and overheating. Together, they enhance system reliability, reduce downtime, and ensure smooth, efficient motor operation in demanding environments.

Drive communication systems enable seamless data exchange between variable frequency drives (VFDs), PLCs, HMIs, and industrial control networks, supporting real-time monitoring, diagnostics, and precise motor control. Utilizing protocols like EtherNet/IP, Modbus, PROFINET, and DeviceNet, these interfaces integrate drives into complex automation architectures, improving system responsiveness, reducing downtime, and enabling predictive maintenance. Robust drive communication ensures interoperability and visibility across industrial environments demanding high-performance motion and process control.

EMC filters, or electromagnetic compatibility filters, suppress conducted electrical noise and reduce electromagnetic interference (EMI) in industrial power systems, ensuring compliance with regulatory standards and protecting sensitive equipment. Installed at the input of drives, power supplies, and control panels, these filters improve signal integrity, prevent malfunction, and enhance overall system reliability in environments with high electrical noise. Essential for maintaining stable operation in automated and mission-critical industrial applications, EMC filters are a key component in modern electrical design.

Braking resistors and regenerative converters manage excess energy generated during motor deceleration in industrial drive systems, preventing overvoltage faults and improving system stability. Braking resistors dissipate surplus energy as heat in high-inertia applications, while regenerative converters feed that energy back into the power grid for improved efficiency and energy savings.

Industrial phase converters enable reliable three-phase power from single-phase sources, allowing heavy-duty equipment like CNC machines, conveyors, compressors, and industrial pumps to operate in facilities without utility-supplied three-phase service. Engineered for high-performance, continuous-duty applications, these converters—available in rotary, digital, and static configurations—deliver balanced voltage, reduced harmonics, and efficient motor performance across demanding manufacturing and processing environments.

$154.57$192.00

$241.11

Subject to factory lead times

$210.10$261.00

$434.21

Subject to factory lead times

$542.58$674.00

$739.80$919.00

$115.88$143.94

Subject to factory lead times

$795.83$892.81

Subject to factory lead times

$237.47$266.40

Subject to factory lead times

$2,210.40$2,479.78

Subject to factory lead times

$2,038.67$2,287.11

Subject to factory lead times

$154.57$192.00

$241.11

Subject to factory lead times

$210.10$261.00

$434.21

Subject to factory lead times

$542.58$674.00

$739.80$919.00

$115.88$143.94

Subject to factory lead times

$795.83$892.81

Subject to factory lead times

$237.47$266.40

Subject to factory lead times

$2,210.40$2,479.78

Subject to factory lead times

$2,038.67$2,287.11

Subject to factory lead times